Newsletter | Vol 6 - July 2017

In this newsletter...

Focus on Data[Permalink]

Technical data can be expensive and difficult to obtain--collecting it, organizing it, analyzing it. Any time you have something someone else doesn't have, you need to retain that advantage and put it to work.

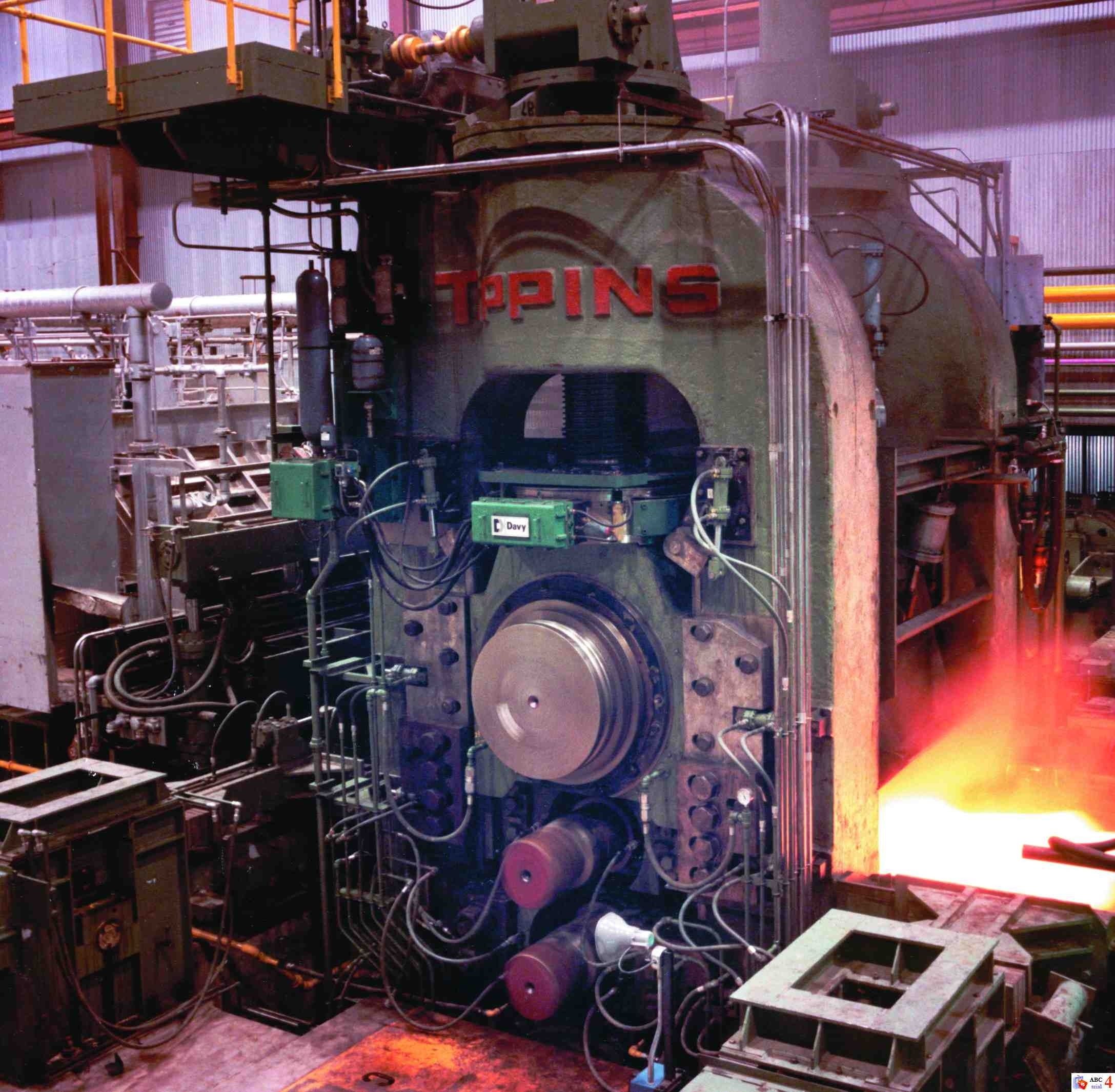

Four high rolling mill (main mill at Haynes International to produce hot rolled plate and feedstock for the cold strip mill).

Product Updates: ASMD, AHAD and HPAD[Permalink]

HPAD and AHAD

- 904L - 904L is a non-magnetic super austenitic stainless steel that was originally developed for use in sulfuric acid environments. It is resistant to stress corrosion cracking and crevice corrosion. It also offers excellent formability, toughness, and weldability.

- Alloy 690 - Alloy 690 is a high Cr, austenitic, solid-solution nickel-base alloy which has excellent resistance to corrosion in aqueous environments and high temperature atmospheres. It is extensively used in the nuclear industry and petrochemical industry for heat transfer tubes, baffles, sheets and other hardware.

- Alloy 825 - Alloy 825 is a nickel-iron-chrome alloy with exceptional resistance to general corrosion in strong acids, high resistance to pitting and crevice corrosion cracking and intergranular corrosion resistance. Alloy 825 has been successfully used in a variety of applications in the chemical processing and oil and gas industries.

- F6NM (wrought version) and CA6NM (cast version) - F6NM is a low C super martensitic stainless steel. It has moderate corrosion performance, good strength, good toughness, and much better weldability than most martensitic stainless steels. It is ferromagnetic and, as a result, can be checked with magnetic particle inspection methods. It is used in many applications in the chemical processing and petrochemical industries.

- Zr 702 and 705 - These are the two most widely commercially used alloys of Zirconium (Zr). They were originally developed for use in nuclear reactors as cladding for uranium fuel and for reactor core components such as fuel rod spacers and water channels. Now the chemical processing industry utilizes Zr and its alloys for reaction columns, heat exchangers, pumps, and other components in severely corrosive environments.

ASMD, HPAD and AHAD

- L-605 revision - L-605 is a high temperature cobalt base superalloy that combines solid solution strengthening with second phase strengthening by precipitated carbides. The alloy has excellent resistance to sulfidation and high strength and oxidation resistance up to 1800F. It is an established alloy used in commercial and military turbine engines.

- 430 Ferritic Stainless Steel - This low-carbon, nickel-free ferritic stainless steel is one of the most widely used of the non-hardenable, straight chromium stainless steels. It has good corrosion resistance and stress corrosion resistance, including high resistance to nitric acid, sulfur gases, and various organic and food acids. The Powder Metal grade, 430L, is widely used for structural and metal injection molded components, and additive manufacturing.

Meet Our Authors[Permalink]

Debo Aichbhaumik has completed seven chapters for CINDAS over the past four years on mostly relevant stainless steel alloys including F6NM, Lean Duplex, 2205, 254 SMO, Ferralium 255 and Dataloy 2. Recently he author a chapter on Inconel 783 that will be released 2018.

Dr. Aichbhaumik received his Ph.D. and M.S. in Metallurgical Engineering from Wayne State University and his B.S. in Metallurgical Engineering from University of Calcutta.

For over 20 years he held numerous positions in Process Development, Quality Assurance, Metallurgical Engineering and Senior Fellow at Weirton Steel Corporation (now ArcelorMittal Weirton).

Debo retired in 2012 from the U.S. Department of Energy, Golden CO Field Office and has been doing independent consulting work.

What's Coming[Permalink]

During the remainder of this year and in subsequent years, CINDAS will be adding new alloys to our databases and totally updating and revising some of the most heavily used chapters.

This year, we will add Ferrium M-54 (see our section of "Materials by Design" Methodology in this newsletter) and Inconel 783.

In 2018, we will be adding a chapter on a relatively new alloy, Haynes 244, and a major update and revision to Ti 38-6-44. Additional alloys forthcoming are 9Cr-1Mo, G-35 and Al-6XN plus more updates and revisions to some of the older chapters in the ASMD.

Let us know if there are any particular alloys that you would like to see added to our databases in the future.

"Materials by Design" Methodology[Permalink]

QuesTek Innovations, LLC is a small business that specializes in computational materials design to rapidly and efficiently innovate, scale-up and deploy novel high-performance materials. Using Integrated Computational Materials Engineering (ICME) technologies, QuesTek integrates computational models within a systems engineering framework to model process-structure and structure-property interactions, allowing for microstructural design across a hierarchy of length scales to meet specific user-defined performance goals.

Read more about "Materials by Design".

"Engineers working in metals and alloys utilize CINDAS data on a daily basis"[Permalink]

John Yadon, who served as a metallurgical engineer and National Division Head for NAVAIR for over 34 years, recently commented on the value of the CINDAS materials properties databases and their unique benefits and features.

Read his comments by clicking here.

Technical data can be expensive and difficult to obtain--collecting it, organizing it, analyzing it. Any time you have something someone else doesn't have, you need to retain that advantage and put it to work.