Newsletter | Vol 10 - June 2019

Additive Manufacturing

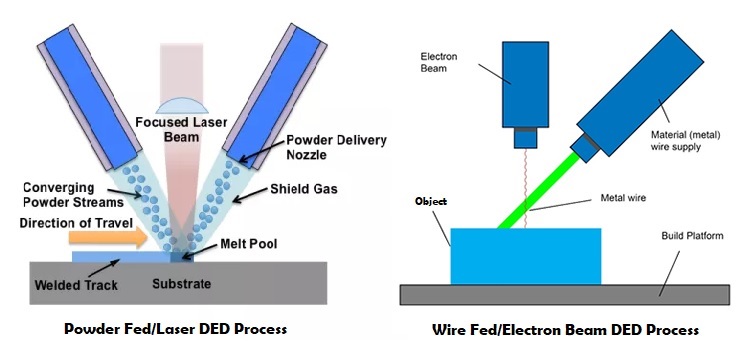

Additive Manufacturing (AM), also known as 3D printing, is a once emerging technology that has become a successful industry composed of many different types of materials and processes. The end result of these processes is to utilize a 3D model of Computer-Aided Design (CAD) data to arrive at a functional or near net part at lower production costs than using formative (extrusion, casting, forging) or subtractive (machining, grinding) manufacturing methods. The major processes used in AM are dominated by two types of processes: Directed Energy Deposition (DED) and Powder Bed Fusion (PBF).

Later this year, CINDAS will add a new chapter to our metallic databases (ASMD, HPAD and AHAD) on Ti-6Al-4V, written with a focus on its properties when produced utilizing various methods of AM. The chapter also offers a good, descriptive review of the various types of processes used in AM. Ti-6Al-4V was chosen for this first AM chapter because it is the most widely used titanium alloy in industry and also the most widely used alloy in titanium AM. This chapter follows the traditional format of our other chapters and contains the same types of property information as all the other chapters in our metallic databases. This chapter does not replace any of the existing Ti-6Al-4V chapters in the database; it is intended to enhance the existing wrought and cast chapters. As a result, using the graphing software in the databases, users of our databases will be able to compare the properties of cast and wrought Ti-6Al-4V to AM-produced versions.

Additive Manufacturing of Ti-6Al-4V

We currently have an additional chapter being developed on AlSi10Mg from an AM perspective. Overall, AlSi10Mg is the most widely used aluminum alloy for metallic AM at this time. It will be published next year as one of the several regular additions of alloys we make to our metallic databases each year.

"You can have data without information, but you cannot have information without data." -- Daniel Keys Moran