Newsletter | Vol 12 - September 2020

New Additions to the TPMD

TPMD NEWS: NEW Material Groups Added

In July 2020, CINDAS LLC added data on 100 new materials, most of them Thermal Barrier Coatings. This is a new material group in the Coatings section of the Thermophysical Properties of Matter Database (TPMD).

Thermal barrier coatings are a relatively new area of research for systems such as gas turbine or aero-engine parts which are operating at elevated temperatures. Application of 100 μm-thick to 2 mm-thick coatings of thermally insulating materials serves to insulate components from extended periods of high heat loads. As such, they can extend the life of the part by preventing thermal fatigue and reducing oxidation.

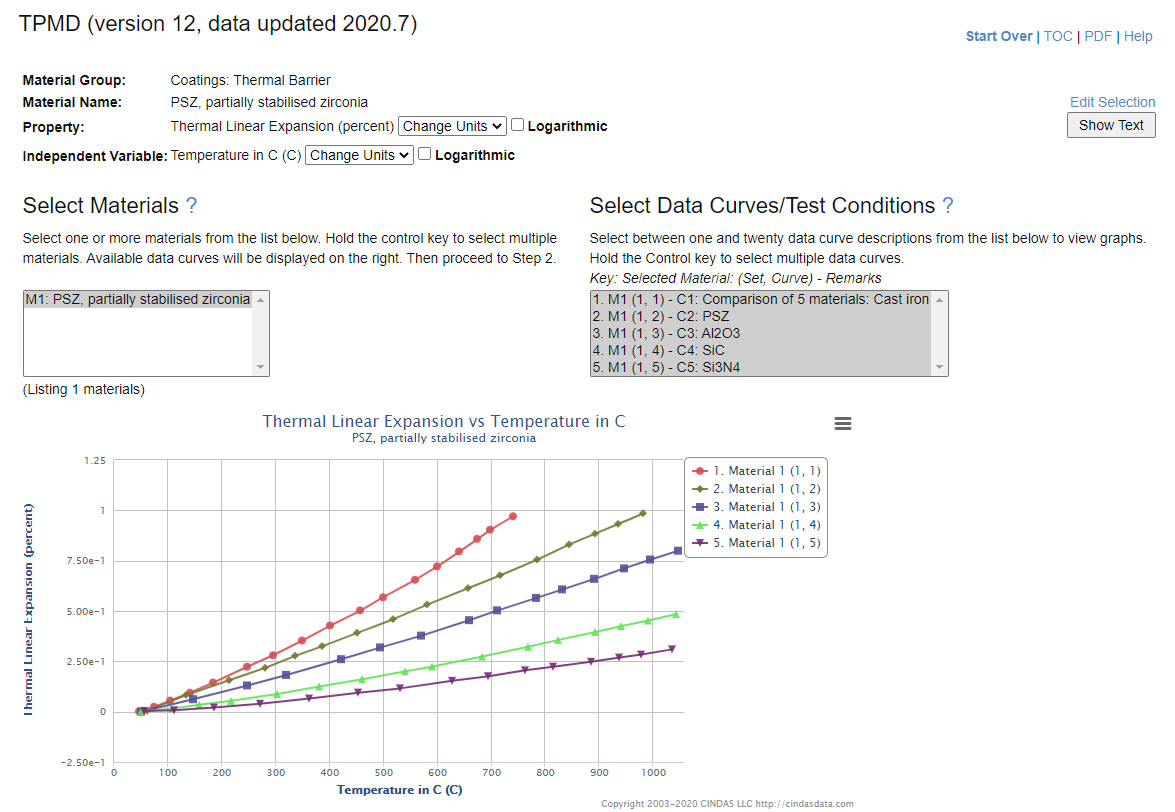

Because of the stresses of thermal expansion during heating and cooling of parts, there must be adequate matching of the thermal coefficients of expansion between the material and the coating. As a result, the general requirements of an effective thermal barrier coating can be summarized as:

b. No phase transition between room temperature and operational temperature

c. Low thermal conductivity

d. Inert chemical reactivity

e. Similar thermal expansion with the metal on which it is applied

f. Good adhesion to the substrate

g. A low rate of sintering for a porous microstructure

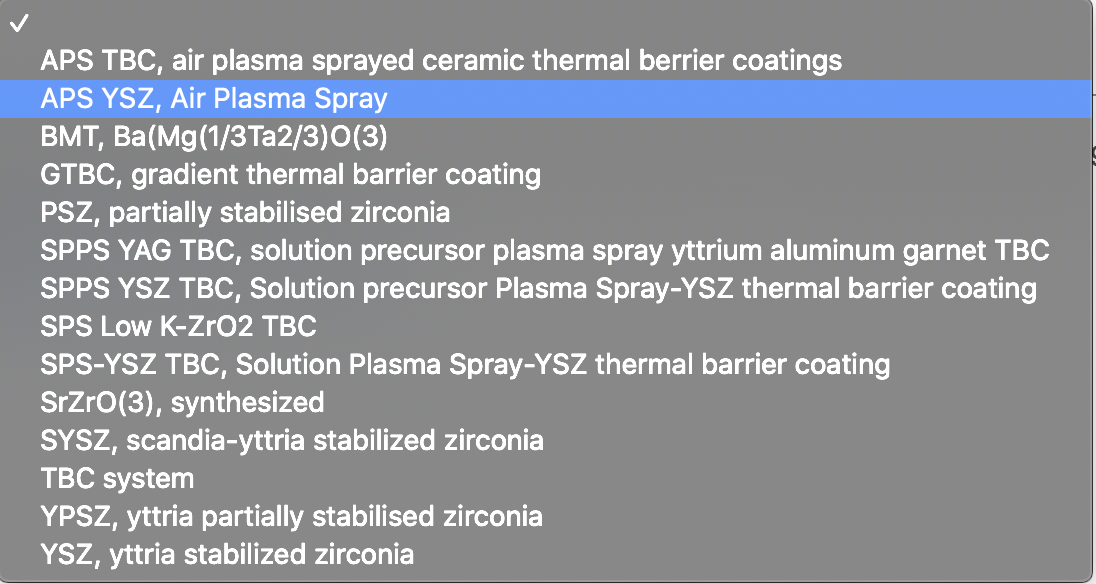

Thus, only a relatively few materials meet all such criteria. In the TPMD there are 14 of these materials as shown below:

It is important to choose the coating material wisely. As shown in the following graph, there are widely different values for thermal linear expansion of the five different coating materials over the selected temperature range (RT to 1000°C).

In the aviation industry, interest in increasing the efficiency of gas turbine engines has resulted in operations at high combustion temperatures, because turbine efficiency is strongly correlated with combustion temperature. The use of thermal barriers to protect nickel-based superalloys from melting and thermal cycling is common. To avoid the melting point difficulties with superalloys, some research is being done on ceramic-matrix composites for high temperature alternatives.

Two different ceramic-matrix composite groups were added to the TPMD: the whisker-reinforced group contains data on 50 materials, while the particulate-reinforced group contains data on 41 materials.

Thermal barrier coatings can also be applied to vehicle exhausts, turbocharger casings, heat shields and other vehicle components to reduce heat transfer and improve vehicle performance. Heat soak from hot exhaust systems transfers into other vehicle components causing reduced performance or damage.

Because thermal barrier coatings are widely used on modern aero engines and land-based turbines, researchers from our various client sectors should consider adding the TPMD to their database subscriptions if they have not already done so.