Newsletter | Vol 21 - June 2024

Head, Shoulders, Knees and Toes! Remarkable Alloys for Joint Replacement

Heads, Shoulders, Knees and Toes! Who knew when this children's song was documented as early as 1912 that it could describe the world of many of us in the 21st century? YouTube video

Many of us know friends and family members who have had body parts replaced with new alloys, many of which are featured in the CINDAS LLC AHAD (Aerospace and High Performance Alloys Database).

The following table shows the need for joint replacements currently and in the future.

Table 1. Locations of various human body fractures that demand different temporary fixation implants.

| Fracture Site | Internal Fixators | |

| Head | Fracture of the skull Craniofacial fracture Fracture of the clavicle Fracture of the scapular Fracture of the pelvis Spinal fracture |

Plates, wires, and pins Plates, wires, and pins Plates and intramedullary nails Plates and screws External fixators, screws, and plates Fixation implant contains plates, pedicle screws, and rods |

| Upper limb fracture | Fracture of the humerus Fracture of the radius or ulnar Fracture of the phalanges and metacarpal fracture |

Plates and screws for open reduction and an intramedullary nail for closed reduction Plates and screws for open reduction and an intramedullary nail for closed reduction External fixators for close reduction and intramedullary nails, plates, and screws for open reduction |

| Lower limb fracture | Femoral fracture Tibial and fibular fracture Fracture of the metatarsus Calcaneal fracture |

Plates and screws for open reduction and an intramedullary nail for closed reduction Plates and screws for open reduction and an intramedullary nail for closed reduction Plates and screws for open reduction and an intramedullary nail for closed reduction Wires and screws for close reduction |

Source: Biomaterials as Implants in the Orthopedic Field for Regenerative Medicine: Metal versus Synthetic Polymers. Polymers 2023, 15, 2601. https://doi.org/10.3390/polym15122601 https://www.mdpi.com/journal/polymers

And this table shows which alloys are currently being used in implanted devices currently. Of those shown the CINDAS AHAD and ASMD contain Stainless Steel 316, Stellite 21 and Ti-6Al-4V; the latter also has a specific chapter on the additively manufactured alloy.

Table 2. Diverse types of bio-metal materials employed in orthopedic implants with their applications, advantages, and disadvantages.

| Metals and Alloys | Particular Alloys | Major Applications | Advantages | Disadvantages |

| Stainless steel | 316 L Stainless steel | Surgical implements, stents, fracture fixation | High wear resistance | The modulus is increased compared to bone allergy due to Co, Cr, and Ni |

| Titanium-based alloys | CP-Ti Ti-Al-Nb Ti-6Al-4V Ti-13Nb-13Zr Ti-Mo-Zr-Fe |

Dental implants, fracture fixation, bone and joint replacement, pacemaker encapsulation | Low density, excellent biocompatibility, high corrosion resistance, low Young?s modulus | Weak tribological characteristics, the toxic impact of V and Al with long-term use |

| Co and chromium alloys | Co-Cr-Mo Cr-Ni-Cr-Mo |

Dental implants and restorations, heart valves, joint and bone replacement | Excellent wear resistance | The modulus is increased compared to bone allergy due to Co, Cr, and Ni |

| Others | Ni-Ti Platinum Pt-Ir Hg-Ag-Sn amalgam |

Orthodontic wires, fracture fixation plates, stents Electrodes Dental restorations |

Low Young?s modulus Excellent corrosion resistance under maximum voltage potential and charge transfer conditions Easily moldable in situ into a desired shape that is resistant to corrosion in the oral environment |

Allergy due to Ni - Concerns related to Hg toxicity |

Source: Biomaterials as Implants in the Orthopedic Field for Regenerative Medicine: Metal versus Synthetic Polymers. Polymers 2023, 15, 2601. https://doi.org/10.3390/polym15122601 https://www.mdpi.com/journal/polymers

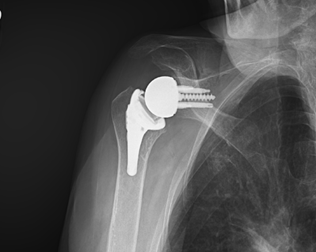

Take for example the shoulder shown in the two images - before and after reverse shoulder replacement surgery in October 2023. Note the slippage of the head of the humerus out of the joint.

The alloy used was Co-28Cr-6Mo, commonly known as Stellite 21. Other alloys commonly used are those of stainless steel, and titanium.

AddUp Inc., headquartered in Cébazat, France, and Anatomic Implants, a medical device startup based in Washington DC, USA, are working together to submit an US Food and Drug Administration (FDA) 510(k) application for what has been referred to as the world's first additively manufactured titanium toe joint (metatarsophalangeal or MTP) replacement. It is made from Ti-6Al-4V ELI with a titanium nitride coating and an Ultra-high- molecular-weight-polyethylene bearing (UHMWPE).

The MTP toe joint is located at the base of the big toe and is one of the three main points used for balance. It is often the first joint in the foot to develop osteoarthritis. With the global market for the first MTP joint reconstruction being over $500 million annually, the market is said to be underserved with very few products, none of which are anatomic or have the potential to support bone-in growth as well as the Anatomic Great Toe Joint. The use of Additive Manufacturing allows for a porous structure to be integrated into the design to promote osseointegration, thereby giving the implants a much higher chance of bonding to the bone, reducing the chances of the implant being rejected by the body. This leads to better patient outcomes after surgery.

Source and to learn more: addupsolutions.com