Newsletter | Vol 12 - September 2020

In this newsletter...

Focus on Data[Permalink]

Technical data can be expensive and difficult to obtain--collecting it, organizing it, analyzing it. Any time you have something someone else doesn't have, you need to retain that advantage and put it to work.

An intramedullary tumor in the femur could be reconstructed using a patient specific lattice implant designed and optimized using RMIT University's JIT methodology as shown. This is one example of additive manufacturing.

What's New: Product Updates[Permalink]

January 2020 - ASMD/HPAD/AHAD - New Ti-6Al-4V (Additive Manufacturing)

This was the first of a series of chapters planned to cover the new and growing manufacturing process of Additive Manufacturing (AM), and is in all three of our alloy databases (ASMD, HPAD and AHAD).

Ti-6Al-4V was selected since it is the most widely used titanium alloy overall and the most widely used titanium alloy utilizing additive manufacturing.

The chapter follows the traditional format of our other chapters containing the same types of property information and also offers a good descriptive review of the various types of processes currently being used for those who are not well versed in this new manufacturing process. More importantly, this AM chapter complements the existing cast and wrought Ti-6Al-4V chapters so that the properties of all three forms of manufacture (wrought, cast and additively produced) of this alloy can be compared to each other graphically in the same figure.

A second chapter on a widely used aluminum alloy used in Additive Manufacturing (AlSi10Mg) will be published in January 2021 and will be presented in all three metallic databases.

May 2020 - ASMD/AHAD - New Alloys (Ferrium C61/C64)

Along with providing information on alloys that are currently in heavy use, we also try to provide information on newer alloys that can offer savings or improved performance in various applications.

Ferium C61 and C64 are newly developed, computationally designed, high performance, secondary hardening, martensitic gear and bearing steels. They were designed to optimize core properties in comparison to 9310 (AMS 6265) and Alloy 53 (AMS 6308). These enhanced properties make them suitable for reducing the weight of components while allowing an increased range of working temperatures and extended service life. Applications include aerospace, energy, oil and gas, and high performance automotive and racing industries.

July 2020 - TPMD - 100 New Materials Added to TPMD

Data on 100 new materials has been added to the TPMD. Much of the information contained in 373 data sets and 893 data curves is on Thermal Barrier Coatings, a new area of research.

See story in this issue about these new materials.

September 2020 - ASMD/HPAD/AHAD - Inconel X-750 Revision

We periodically review the alloys in our databases to determine if additional data has become available on a specific alloy since it was last published. If so, we arrange to do an update to the chapter on that alloy.

That is the case with Inconel X-750. It is a precipitation hardenable nickel-chromium alloy containing aluminum and titanium. Although it is an older alloy, it is still heavily used by the subscribers to our databases. This update/revision, just published this month, brings the chapter on this alloy up to date to include additional data and information that has become available since the original chapter was published in June 1981. Inconel X-750 is used in aerospace as well as other applications. The alloy is ranked in the top 100 alloys accessed by our users.

Modification to Search Menu Screen for Additive Manufacturing Chapters[Permalink]

In the first quarter of 2020, CINDAS added an additional chapter on Ti-6Al-4V to the ASMD, HPAD and AHAD. This chapter was written to cover the properties of this alloy when processed using Additive Manufacturing (AM). This provided three distinct chapters on Ti-6Al-4V: wrought, cast and additively manufactured.

This initial AM chapter will be followed by another one in early 2021. This second chapter will be on AlSi10Mg (AM) and will cover the properties of this alloy as processed by various methods of AM. Chapters on additional alloys from an AM perspective are planned, depending on the interest and use of our subscribers.

In order for users to more easily find these first two AM chapters and future additional AM chapters, we have made a slight change to the "Material Group" selection box on the main search screen. The alloys that have chapters dealing with AM will be in bold print so that they are easier to find. At this time, the only AM chapter is on Ti-6Al-4V (AM) and is in bold. In early 2021, the second AM chapter on AlSi10Mg will be added and will also be in bold, and so forth on additional AM chapters.

We would appreciate your feedback on the AM chapters in the databases so that we can assess the value of these chapters to our subscribers.

Legacy Alloys: Nickel/Cobalt-Based Alloys[Permalink]

The CINDAS AHAD database includes over 300 alloys. Many of these alloys were developed more than 50 years ago, but they are still widely used and popular in applications throughout different industries. This article will feature the Top 10 ?legacy? alloys in the nickel/cobalt category that CINDAS customers refer to and access through the AHAD database. Future newsletters will highlight legacy alloys from other material classes (aluminum, stainless steel, titanium and high strength steels).

718

Inconel 718 is the most widely used superalloy. It is recognized for its excellent strength, ductility and toughness throughout the temperature range -423°F to 1300°F. Ideal for its processing versatility, it is used in structural applications for aerospace, nuclear and petrochemical industries. It is available in cast and wrought forms.

Inconel 625

Inconel 625 is a nickel-based superalloy with good strength, creep and fatigue properties from cryogenic to elevated temperatures. It is used widely in the chemical, nuclear and aerospace industries.

A-286

A-286 is a high toughness austenitic stainless steel (25% Ni, 15% Cr). It is used in temperature ranges up to 1300°F. Applications include aircraft turbine engine components such as disks, vanes, blades, shafts and combustors.

Hastelloy X

Hastelloy X is a nickel-based superalloy with oxidation resistance up to 2200°F and moderate strength up to 1600°F. It is used in the aerospace combustion and turbine sectors, as well as in the industrial, chemical and petrochemical industries.

Inconel 600

Inconel 600 is a nickel chromium alloy widely used because of its excellent corrosion and oxidation resistance. It has corrosion resistance in many organic and inorganic environments. Applications are found in the aerospace, chemical, heat treating equipment and nuclear industries.

Haynes 188

Haynes 188 is the most widely used cobalt-based alloy in the aircraft engine market. It has excellent strength, weldability and oxidation resistance. It has a 100°F higher creep resistance strength advantage over Hastelloy X.

Waspaloy

Waspaloy has good tensile strength and fatigue at intermediate temperature ranges. It is used for disks in turbine and compressor sections of turbine engines.

Haynes 230

Haynes 230 has excellent resistance to oxidizing environments up to 2100°F. The alloy retains high ductility and toughness following long exposures in the 1200-1600°F range. Primary applications include combustors, transition ducts and temperature sensors in gas turbine engines and nozzles for rocket engines.

X-750

X-750 can be used up to 1300°F and has excellent sub-zero properties. Applications include aerospace rotor blades, wheels and bolts in gas turbine engines. It is also used in thrust reversers, springs and fasteners.

IN-100

IN-100 is widely used as a compressor and gas turbine disk material for jet engines. This alloy has a good balance of strength, creep resistance and fatigue crack growth properties.

MMPDS vs. AHAD[Permalink]

CINDAS often gets questions about the difference between the MMPDS and the AHAD. In many regards the MMPDS and AHAD complement each other. The Metallic Materials Properties Development Standardization Handbook (MMPDS) is the primary source of statistically based allowables for metallic materials and fastened joints used in the design of aerospace vehicle structures in the US. In general the Aerospace and High Performance Alloy Database (AHAD) contains more materials (over 300 alloys) and more material properties characteristic data. Examples of the differences for heat-resistant alloys are:

MMPDS-14 (heat-resistant alloys)

- 15 alloys

-

Major alloys:

A-286

Hastelloy X

Inconel 600

Inconel 625

718

X-750

Rene 41

Waspaloy

L-605

AHAD (heat-resistant alloys, nickel- and cobalt-based)

- 80 alloys

- all 15 from MMPDS

Hastelloy X

-

MMPDS

- 1 page of text

- 6 tables and figures

- only allowables data -

AHAD

- 7 pages of text

- 97 tables and figures

- covers full range of properties, conditions and environments -

AHAD

- information on:

microstructure

corrosion

heat treatment

fatigue

fracture toughness

FCG

forming

welding

Effects of COVID-19 on CINDAS LLC[Permalink]

Everyone's personal and professional life has been impacted by Covid-19. The CINDAS team remains safe and healthy. Many of our customers have employees working from home and other remote sites. The good news is that the CINDAS databases can be accessed from anywhere. Looking at the AHAD (most popular CINDAS database), the usage through July 2020 is up 26% from the same time period in 2019. Irregardless of where the CINDAS databases are being accessed, we are encouraged that our customers continue to use our critical materials characteristics property data.

New Additions to the TPMD[Permalink]

TPMD NEWS: NEW Material Groups Added

In July 2020, CINDAS LLC added data on 100 new materials, most of them Thermal Barrier Coatings. This is a new material group in the Coatings section of the Thermophysical Properties of Matter Database (TPMD).

Thermal barrier coatings are a relatively new area of research for systems such as gas turbine or aero-engine parts which are operating at elevated temperatures. Application of 100 μm-thick to 2 mm-thick coatings of thermally insulating materials serves to insulate components from extended periods of high heat loads. As such, they can extend the life of the part by preventing thermal fatigue and reducing oxidation.

Because of the stresses of thermal expansion during heating and cooling of parts, there must be adequate matching of the thermal coefficients of expansion between the material and the coating. As a result, the general requirements of an effective thermal barrier coating can be summarized as:

b. No phase transition between room temperature and operational temperature

c. Low thermal conductivity

d. Inert chemical reactivity

e. Similar thermal expansion with the metal on which it is applied

f. Good adhesion to the substrate

g. A low rate of sintering for a porous microstructure

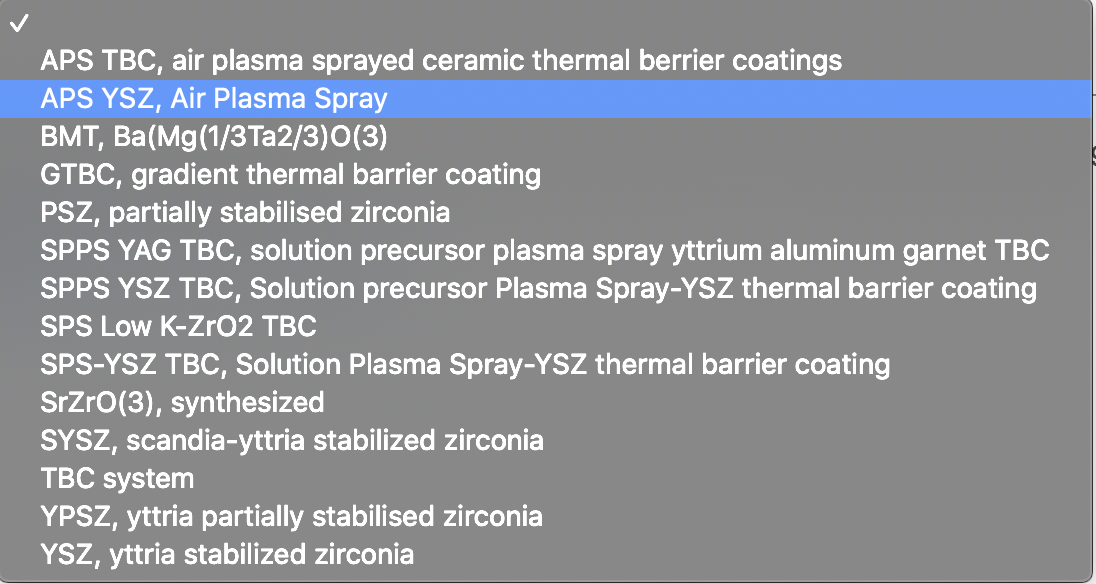

Thus, only a relatively few materials meet all such criteria. In the TPMD there are 14 of these materials as shown below:

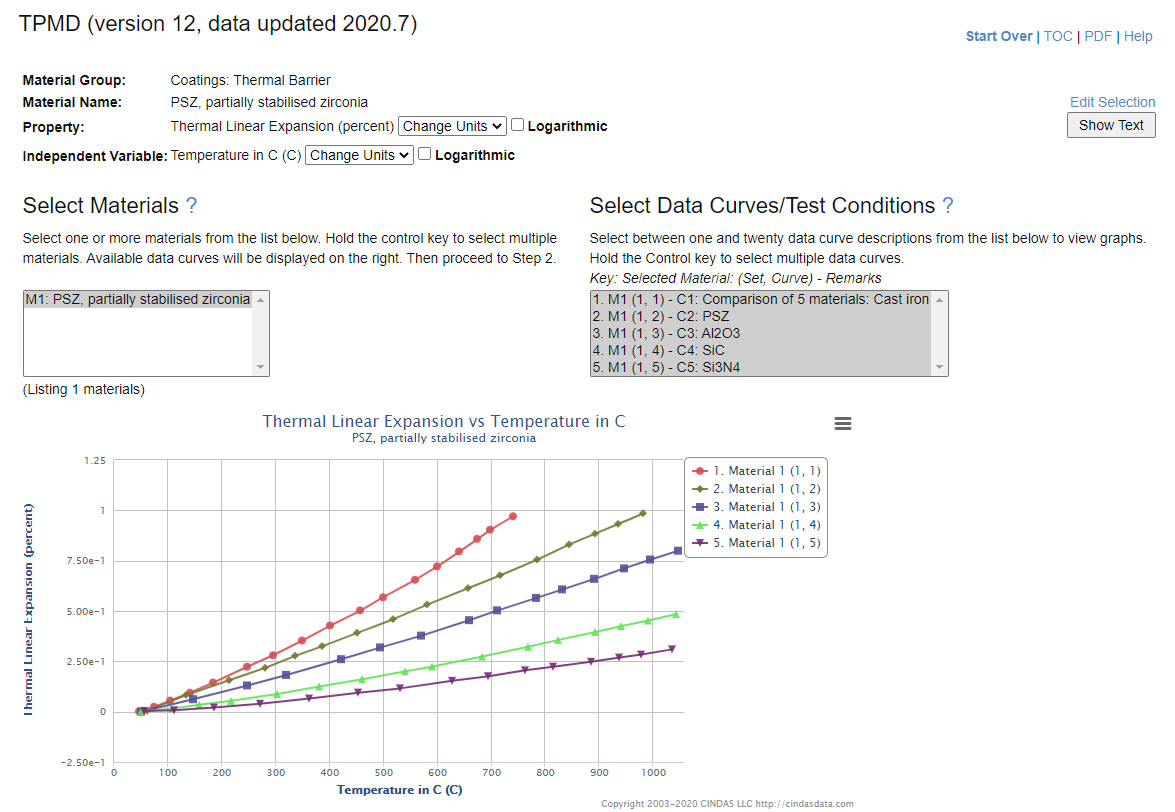

It is important to choose the coating material wisely. As shown in the following graph, there are widely different values for thermal linear expansion of the five different coating materials over the selected temperature range (RT to 1000°C).

In the aviation industry, interest in increasing the efficiency of gas turbine engines has resulted in operations at high combustion temperatures, because turbine efficiency is strongly correlated with combustion temperature. The use of thermal barriers to protect nickel-based superalloys from melting and thermal cycling is common. To avoid the melting point difficulties with superalloys, some research is being done on ceramic-matrix composites for high temperature alternatives.

Two different ceramic-matrix composite groups were added to the TPMD: the whisker-reinforced group contains data on 50 materials, while the particulate-reinforced group contains data on 41 materials.

Thermal barrier coatings can also be applied to vehicle exhausts, turbocharger casings, heat shields and other vehicle components to reduce heat transfer and improve vehicle performance. Heat soak from hot exhaust systems transfers into other vehicle components causing reduced performance or damage.

Because thermal barrier coatings are widely used on modern aero engines and land-based turbines, researchers from our various client sectors should consider adding the TPMD to their database subscriptions if they have not already done so.

Training Resources Available[Permalink]

Under our link (LEARN) on our webpage: https://cindasdata.com/learn, you can find everything you need to know about how to use the CINDAS LLC databases and on-line handbooks.

Please check out:

https://cindasdata.com/learn/docs/CINDAS_databases_whats_in_them_for_me_inclusive.pdf.

This PowerPoint presentation on the databases was recently updated.

REQUESTS FOR TRAINING

Please review the CINDAS instructional video demonstration of a live training session on the new CINDAS LEARN link: https://cindasdata.com/learn.

If you need additional site training, contact us to schedule a phone conference or a webinar: https://cindasdata.com/support/training.

New Mailing Address[Permalink]

We've had a slight change to our mailing address; it is now:

CINDAS LLC

PURDUE TECHNOLOGY CENTER-AEROSPACE

1801 NEWMAN ROAD SUITE 1150

WEST LAFAYETTE IN 47906-4524 USA

Technical data can be expensive and difficult to obtain--collecting it, organizing it, analyzing it. Any time you have something someone else doesn't have, you need to retain that advantage and put it to work.