Newsletter | Vol 13 - June 2021

In this newsletter...

Focus on Data[Permalink]

Technical data can be expensive and difficult to obtain--collecting it, organizing it, analyzing it. Any time you have something someone else doesn't have, you need to retain that advantage and put it to work.

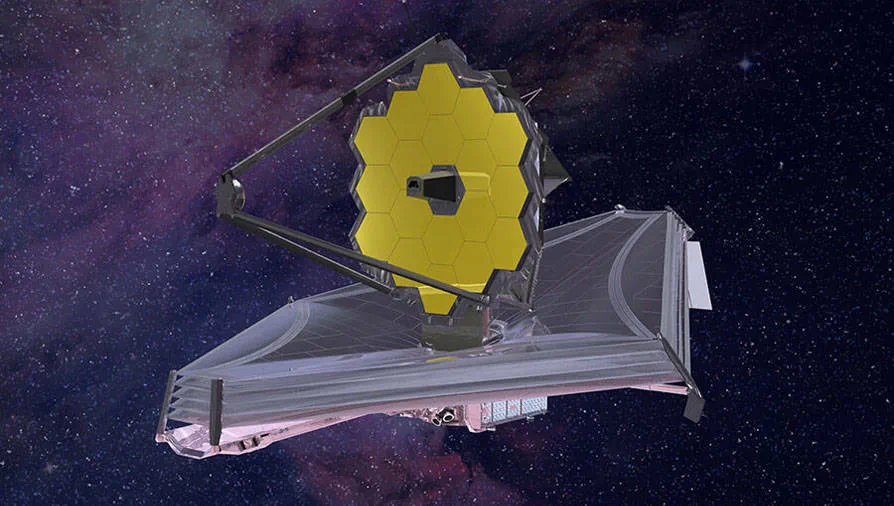

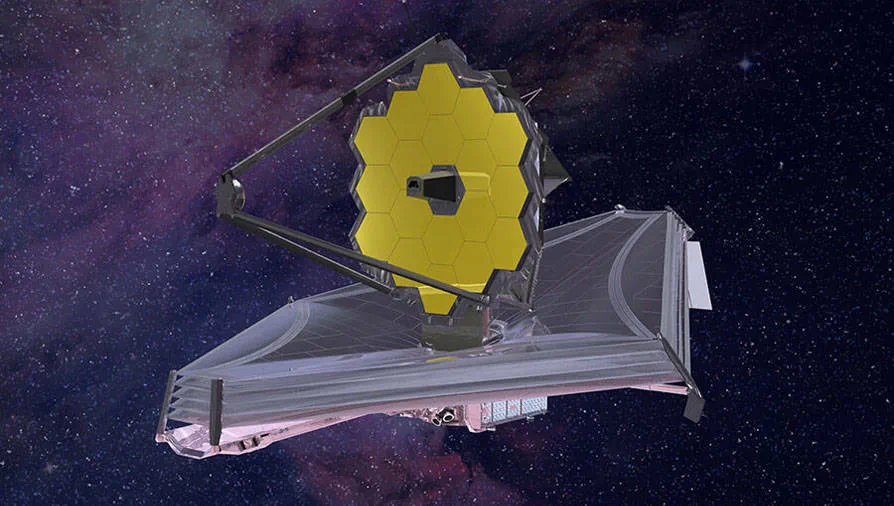

The James Webb Space Telescope is scheduled for launch in late 2021 by NASA and will peer into space from almost a million miles from planet earth. To learn more, read the article in this issue.

Cryogenic and Low Temperatures Database (CLTD)[Permalink]

CINDAS LLC is proud to announce the introduction of our newest database, the Cryogenic and Low Temperatures Database (CLTD). This database was developed over the past two years based on suggestions and input from our current customers.

It contains thermophysical, mechanical, electrical and other properties data on over 2000 materials in the temperature range from 0 K to 273 K. The initial data is from both NIST data resources and CINDAS data. More data will be added as it becomes available.

Users will find the data in the same CINDAS easy-to-navigate format as our other databases. Properties included are 37 thermophysical, 10 thermoradiative, 26 electrical and nuclear, and mechanical properties such as modulus, strength, stress, hardness, crack, and fatigue as well as others. The fact that the data is in a single resource will save researchers time and money when seeking cryogenic or low temperature data.

The following link to a PowerPoint presentation regarding the CLTD will provide more information on the 54 material groups in the database: https://cindasdata.com/products/docs/CLTD-powerpoint.pdf.

To see the demo version of the database, click here.

If you are interested in learning more about this product, please contact us.

Markets and Applications for Cryogenics[Permalink]

Background

Some properties, such as electrical conductivity and thermal conductivity, can change by several orders of magnitude when cooled from room temperature to 4 K or below.

Benefits of Cryogenic Temperatures

- Preservation of biological material and food

- High fluid densities ? liquified gases

- Superconductivity and superfluidity ? no resistance to the flow of electricity and no resistance to the flow of the fluid

- Reduction of thermal noise

- Low vapor pressures

- Temporary and permanent property/phase changes

- Tissue destruction

Applications

Liquify Gases

Common permanent gases change from gas to liquid at cryogenic temperatures (a permanent gas is one whose critical temperature is far below room temperature). These liquids are known as cryogenic liquids. Temperatures these gases liquify are listed below:

- Methane 112 K

- Oxygen 90 K

- Nitrogen 77 K

- Hydrogen 20 K

- Helium 4.2 K

Space

Space applications that rely on cryogenic materials and technology include:

- Antennas

- Rockets

- Satellites

- Space craft

- Sensors

- Astrophysics and space telescopes

Medical

The superconducting magnet coils in most magnetic resonance imaging (MRI) systems require temperatures of 4 K with GM cryocoolers that condense the boil off from a bath of liquid helium. An electromagnet wound with a wire of extremely low electrical resistance can produce extremely high magnetic fields with no generation of heat and no consumption of power once the field is established and the metal remains cold. These metals, typically niobium alloys cooled to 4.2 K are used for the magnets of MRI systems. Copper electromagnets are impractical because of the massive heat generated and the cooling systems required to remove the heat. MRI is the largest commercial application of superconductivity (22,000 units worldwide and 1000+ added each year). About 100 tons/yr of NbTi alloy are required to produce the superconducting magnets.

Military

Infrared sensors are used for military night vision equipment which require cooling to 80-150 K. The Stirling-type pulse tube cryocoolers are used for this application. Night vision relies on detecting thermally radiated electromagnetic spectra. There have been spinoffs of this cooled infrared technology for police, rescue and security operations.

Industrial and Transportation

Magnetic levitation requires superconductivity and superconducting magnets. Monorail trains rely on this technology.

Other industrial applications include:

- Furnace atmospheres

- Heat treating

- Cooling detectors

- Chemical processing

- Scanning electronic microscopes

Electronics

Superconducting electronics or power systems utilize regenerative cryocoolers.

What's New: Product Updates[Permalink]

February 2021: New Chapter on AlSi10Mg (Additive Manufacturing) (ASMD/HPAD/AHAD)

The new chapter on AlSi10Mg is the second chapter added to our metallic databases that covers an alloy from the perspective of Additive Manufacturing (AM). This is the most widely used aluminum alloy currently used in AM. It is estimated that 25% of 3D metal printers work with aluminum alloys and AlSi10Mg is the most commonly used. The chapter also covers the status of specifications covering this quickly growing technology.

May 2021: New Chapter on Super Austenitic Steel AL-6XN® (HPAD/AHAD)

AL-6XN® is a high performance super austenitic stainless steel that is a nitrogen-enhanced version of the older AL-6X alloy that it has largely replaced commercially. It has good corrosion resistance and resistance to chloride stress corrosion cracking. The alloy is used in numerous applications: chemical processing, oil and gas, medical sterilization equipment, power generation and particularly in desalination, marine envlronments, reverse osmosis and heat exchangers.

Marketplace News on Additive Manufacturing[Permalink]

The newly launched 2021 Alfa Romeo Racing F1 race car, the C41, will include 304 additively manufactured metal parts, which is more than double the number for the 2020 car (C39) which featured 143 AM parts. Twenty-two percent (22%) of the parts are made from Titanium 6-4 (AM) and 40% from Aluminum AlSi10Mg (AM). Cost savings of up to 90% have been realized with AM parts versus traditionally manufactured parts.

The Boeing Company has issued material specification (Boeing BAC 5673) for Aluminum AlSi10Mg additively manufactured components.

CINDAS has two popular new chapters in the AHAD and the ASMD for Aluminum AlSi10Mg (AM) and Titanium 6-4 (AM).

What's Coming ....[Permalink]

So far this year, we have published chapters on AlSi10Mg (Additive Manufacturing) to the ASMD, HPAD and AHAD, and a chapter on AL-6XN® in the HPAD and AHAD. Here are the chapters on alloys that we will be adding during the remainder of 2021 and in 2022:

Al 2198

This is a third generation Al-Li alloy that provides a 3% density reduction and a 6% increase in elastic modulus over conventional high strength Al-Cu alloys. It will be added to the ASMD and HPAD in the last quarter of 2021.

440 A, B, C, & F Stainless Steels (Update)

This existing chapter in the ASMD and AHAD is one of our most heavily used chapters. Since its original publication, a significant amount of work on this alloy has occurred; as a result, the chapter is being updated to include the new information. It will be published in early 2022.

CMSX 2 & 3

These are two of the first generation single crystal superalloys developed for turbine blades which are still widely used. This chapter will be added to the ASMD and AHAD in mid-2022.

Al 2050

This is a relatively recently developed Al-Cu Li alloy that offers weight reduction opportunities in a wide range of thicknesses of sheet and plate. It will be added to the ASMD and AHAD in late 2022.

James Webb Space Telescope[Permalink]

The James Webb Space Telescope is scheduled for launch in late 2021 by NASA and will peer into space from almost a million miles from planet earth. In order to make successful observations, the mirrors will be gold coated and capable of handling 30 K temperatures (-406°F) and will collect radiation emitted by the earliest stars. NASA used glass for the Hubble Space Telescope, but that operates at room temperature. NASA needed a material that would maintain a stable shape at temperatures approaching absolute zero and could withstand the challenging journey into space during launch.

A material for the mirrors needed to be selected that could be manufactured at room temperature, but would change shape in a predictable way as it reached its destination. Beryllium was selected because of its high stiffness (modulus) and lower density. Once below 90 K (-300°F), it stops shrinking. This is important because the Webb is insulated by a sun shield and will operate at about 30 K (-406°F) and will only see temperatures swings of +/- 30K. The telescope will never reach a temperature in space that will cause the mirrors in it to expand.

Training Resources Available[Permalink]

Under our link (LEARN) on our webpage: https://cindasdata.com/learn, you can find everything you need to know about how to use the CINDAS LLC databases and on-line handbooks.

Please check out:

https://cindasdata.com/learn/docs/CINDAS_databases_whats_in_them_for_me_inclusive.pdf.

This PowerPoint presentation on the databases was recently updated.

REQUESTS FOR TRAINING

Please review the CINDAS instructional video demonstration of a live training session on the new CINDAS LEARN link: https://cindasdata.com/learn.

If you need additional site training, contact us to schedule a phone conference or a webinar: https://cindasdata.com/support/training.

New Mailing Address[Permalink]

We've had a slight change to our mailing address; it is now:

CINDAS LLC

PURDUE TECHNOLOGY CENTER-AEROSPACE

1801 NEWMAN ROAD SUITE 1150

WEST LAFAYETTE IN 47906-4524 USA

Technical data can be expensive and difficult to obtain--collecting it, organizing it, analyzing it. Any time you have something someone else doesn't have, you need to retain that advantage and put it to work.